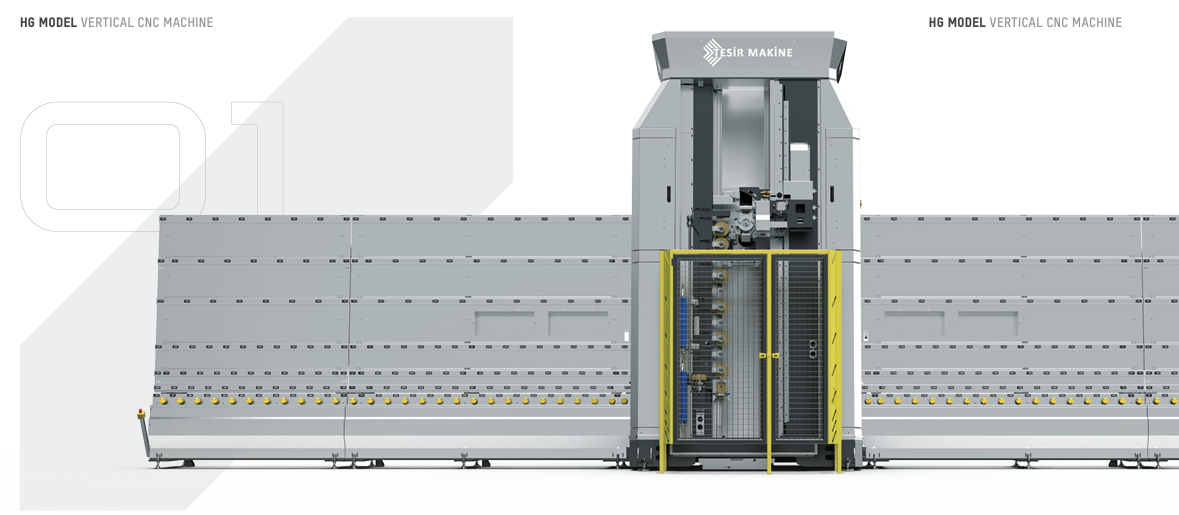

HG MODEL

The vertical HG CNC is designed for efficient,all in one glass processing, handling tasks like seaming, grinding, polishing, drilling, milling and countersinking. Supported by CAD/CAM software, it features a 10 tool magazine with an automated tool change system and a us erfriendly control interface. Ideal for both small operations and large factories, this cost-ef fective solution enhances roduction speed and versatility, making it perfect for businesses

to upgrade their glass processing technology.

TECHNICAL SPECIFICATIONS

| Min. Glass Thickness: | 3 mm |

| Max. Glass Thickness: | 19 mm |

| Min. Glass Height: | 300 mm |

| Max. Glass Height: | 2500 – 2800 – 3300 mm |

| Min. Glass Length: | 700 mm |

| Max. Glass Length: | 4000 – 6000 mm |

| Min. Hole Diameter: | Ø3 |

| Max. Hole Diameter: | Ø75 |

| Energy Supply: | 58 kW |

| Weight: | 6500 kg |

| Spindle RPM: | 12000 |

| Number of Magazines: | 10 |

ADVANTAGES

- Shaped Glass Processing

- Grinding, Arrising, Polishing, Drilling

- Milling, Countersinking

- Automatic Thickness & Size Detection

- Low-E & Coated Glass Processing

العربية

العربية TUR

TUR