SN 100

The SN 100 is used for the grinding and polishing of shaped and flat glass with its strong construction and precise machining capability.

- Fast and precise machining: Max. 1400 * 2400 mm glass is clamped very precisely by special clamp system. In addition, due to the 3-tool holder system, 12 mm thick glass can be processed in 3 stages without needing to change the tools.

- Two Stations: Glasses in small dimensions are connected to two stations at the same time and processed.

- Aluminum table: Due to the 20 mm thickness high quality aluminum table the machining processes are precisely carried out.

- Corrosion-resistant: All surfaces in contact with water are made from corrosion-resistant material.

- Magazine system: With this optional feature, tools changes are automatically performed through the magazine.

- Low Processing and Energy Cost: Due to the servo-driven technology,the power consumptions is extremely low. As all processes are carried out automatically, only one person is getting a high production rate.

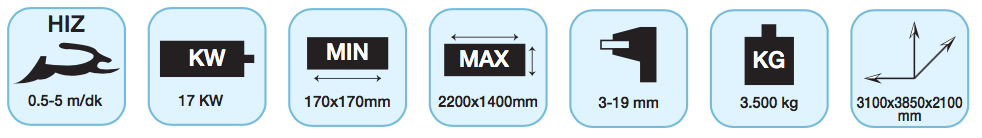

SN 100 TECHNICAL DATA AND PERFORMANCE

| Glass sheet width max.: | 2200 mm |

| Glass sheet width at the reference line min.: | 170 mm |

| Glass sheet length max.: |

1400 mm |

| Glass sheet length at the reference line min.: | 170 mm |

| Glass sheet thickness: | 3-19 mm |

| Glass Seaming/Deburring Speed : | 0,5-5 m/min. |

| Weight : | 3.500 Kg |

| Operating voltage, network parameters: | 17Kw |

ADVANTAGES

العربية

العربية TUR

TUR